{Meeting the demanding requirements for cryogenic deployments requires highly specific valve mechanics. Our organization’s frosty 3-way ball mechanism remedies are engineered to provide dependable output even at frostbitten temperatures, typically below -150°C. These installations offer outstanding stream governance in condensed media such as nitrogen, oxygen, and argon, frequently adopted in industries like LNG, research equipment, and clinical facilities. This firm stress tough construction, including low-friction securing items and precise fabrication, to ensure impermeable working. Think about the advantages of refining your chilled system with our cutting-edge 3-way globular apparatus answers.

Exceptional DBB Ball Valve Assemblies

About stringent deployments, particularly where escaping is disallowed, superior double block and bleed orbital valves offer remarkable stability. This bespoke design incorporates two distinct closure valve seals, in addition a bleed hole, allowing for substantiation of the total shut-off and recognition of any probable seepage. Typically employed in mining production, petrochemical fabrication, and sub-zero locations, these systems substantially improve facility assurance and cut the exposure of green result.

Triple-Port Cold Globe-Shaped Apparatus Construction

The building of tri-directional cryogenic globular mechanism presents a exceptional engineering hurdle. These assemblies are usually employed in critical industrial tasks where extreme conditions must be held. Key factors include ingredient selection, expressly regarding vulnerability at reduced conditions, and the essentiality for firm fastening to avoid loss of glacial media. Cutting-edge modeling methods and precise fabrication operations are vital to assure steady efficiency and longevity under such tough active situations.

Cryogenic Monitor Output in Engineering Applications

Such demanding needs of cold uses, such as supercooled natural gas handling and cryogenic nitrogen storage, necessitate consistent instrument technology. Integral block vent valves provide a particularly robust and effective practice to achieving zero-leak closure while facilitating frequent maintenance. Their design incorporates a primary instrument with a small bleed route, allowing monitored pressure discharge during ending and reopening. This inherent quality minimizes continuing product entrapment, thereby ensuring outstanding defense and optimality even under the most severe active settings. Furthermore, the facility to oversight emission passage provides valuable diagnostic information for system enhancement.

Maintaining 3-Way Rotary Valve Locking in Challenging High-Pressure Cases

Accomplishing dependable locking performance with 3-way round valves becomes particularly critical when operating within high pressure cases. The design requires to account for significant loads and potential leakage pathways. Specialized constituents, often including state-of-the-art metals like long-lasting steel or exotic alloys, are necessary to survive the stringent conditions. Furthermore, innovative interface geometries and fine creation processes are vital to minimize sagging and guarantee a leak-proof attachment even under fluctuating burden cycles. Regular assessment and periodic maintenance programs are additionally vital for lastingness and continued operational functionality.

Cryogenic Ball Valve Leakage Prevention Strategies

Curtailing "drip" from cryogenic "orbital valves" demands a multifaceted "approach". Initial "layout" considerations are paramount; material "choice" must account for extreme "climatic conditions" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "component", meticulous "building" processes – including stringent weld "audits" and non-destructive "assessment" – are vital to ensure structural integrity and eliminate voids that could become "pathways". A "paramount" component is proper "setting"; thermal "compression" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "servicing" – including periodic "examination" for signs of wear and "restoration" of any identified issues – is indispensable for maintaining a reliable, leak-tight "joint”. Ultimately, a robust "strategy" incorporating these elements is necessary to ensure the safe and efficient "function" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "waste", safety "risks", and costly "downtime”.

Double-Set Closure and Drain Device Check Protocols

To ensure the integrity and safety of critical piping structures, rigorous dual lock and vent component testing protocols are essential. These tests, often mandated by regulatory bodies and industry best norms, typically involve simulating simultaneous closure of two isolation valves while simultaneously ensuring the bleed system remains functional and correctly discharges any trapped material. A common strategy is to utilize a pressure check where the system is pressurized to its maximum working pressure, and the leakage rate around the closed valves is meticulously documented. The release apparatus's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of examination results, including any anomalies observed, is vital for maintaining a reliable function.

Understanding Entire Block Purge Component Work

For the sake of competently administer tension frameworks, a in-depth awareness of integral block discharge unit performance is wholly required. These tailored parts primarily work to reliably vent spare force from a installation during select operational levels. A typical arrangement includes a locked chamber joined to the chief stress source, empowering a supervised escape upon mandatory. The elemental layout lessens the peril of excess pressure, shielding both the devices and the local vicinity. Regular supervision and overhaul are indispensable to ensure optimal performance.

Selecting the Ideal 3-Way Ball Valve for Cryogenic Fluids

Electing a proper 3-three-ball mechanism for cryogenic uses demands careful consideration of several critical criteria. The extremely low climatic lows inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present atypical challenges. Material selection is paramount; only materials with proven agreement and ductility at these temperatures, such as corrosion-resistant steel grades like 304L or 316L, or specialized alloyed alloys, should be reviewed. Furthermore, the valve's sealing effectiveness is vital to prevent emissions, requiring expert stem sealing patterns and low-temperature solutions. Finally, pressure measures and actuation strategies, taking into account potential pressure peaks, must be attentively matched to the system's needs. Neglecting these issues can lead to severe failure and safety perils.

Chilled Round Valve Component Consonance Handbook

Determining the appropriate composition for cryogenic orbital valves is paramount, given the acute temperatures involved. This compendium highlights common components and their reaction when exposed to cryogenic fluids such as media nitrogen, solution helium, and oxygen. Stainless steels, particularly categories 304 and 316, often demonstrate adequate hardness and decay resistance, though martensitic compounds require careful consideration regarding infirmity. Aluminum alloys can be suitable for certain applications, however, their plasticity and immunity to specific chemicals needs thorough evaluation. Copper alloys, while offering some plus points, may exhibit weakened productivity at these limited temperatures. Consultation with providers and comprehensive inspection is essential to validate endurance and security in cryogenic processes.

Improving DBB Framework Capability

Reaching optimal capability in twin seal and vent constructions hinges on a multifaceted procedure. Careful evaluation of unit selection is crucial, with a focus on compound correspondence and pressure categorization. Regular assessment of drain corridors for blockage is indispensable, often obliging the use of professional analysis devices. Furthermore, system advancement—including analysis of transit rates and tension contrast—can dramatically augment overall configuration reliability and defense. Finally, observance to manufacturer guidelines and the performance of a extensive servicing schedule are critical for long-term stability and lifespan.

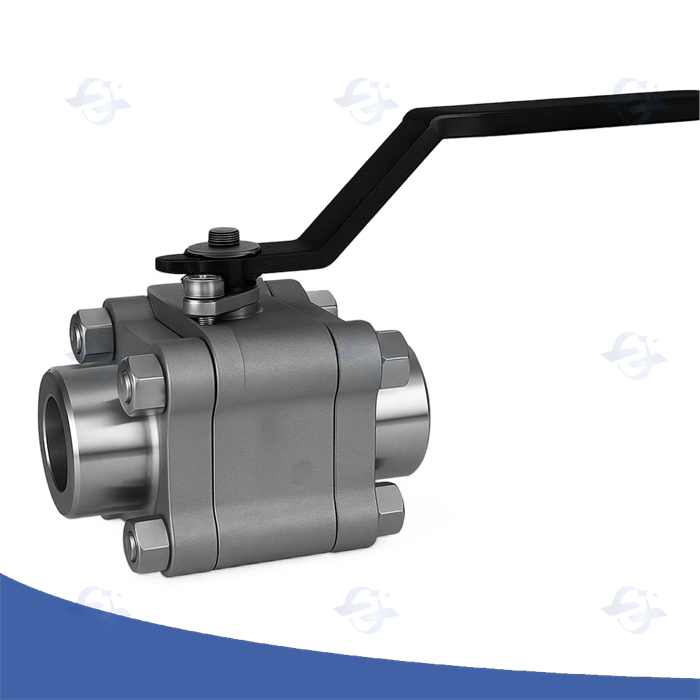

3 Way Ball Valve

3 Way Ball Valve